Alkin = Bauer Filter

Moderator: captain

- rhwestfall

- Master Diver

- Posts: 643

- Joined: Thu Jan 16, 2014 2:34 pm

- First Name: Robert

- Location: "La Grande Ile"

Re: Alkin = Bauer Filter

I'd actually measure the delta in ambient air temperature, and the air temp entering filtration. The equation (and Bauer's information) is based on a specific temperature increase from Bauer's design development and testing. You could substitute an actual temperature change value into the equation to adapt to Alkin's "superior temperature control" because of their claimed "special fins"...

Bob

No Longer Awaiting my Kraken.....

No Longer Awaiting my Kraken.....

- 2THDIVR

- Master Diver

- Posts: 144

- Joined: Sat Jan 02, 2010 4:01 pm

- First Name: Scott

- Location: Venice,FL

Re: Alkin = Bauer Filter

Ran the compressor with the moisture checker after the filter change.

The test disk would not turn back to blue.

Put the disk in my toaster oven at 325 and it started to change back to blue.

Think the temp was a little high because it then turned brown.

Checking the August site for a new disk $13.95, shipping $20.25 was more than I was going to spend

on something that might not be working.

I have setup something different, a 2 1/2" X 10" clear filter housing with 1/2" openings, 2 digital temp and moisture gauges, humidity indicator cards, a 1/2" tank valve and a piece of tubing.

I put the valve on the outlet side of the housing and the tube on the inside the route the air to the bottom of housing.

Put both gauges and a card inside, close it up and hook it to the fill hose.

Seems to work fine, ran for 3 min., the gauges dropped to 10 % there lowest reading and the card was all blue 10% lowest reading.

Housing $15.69, gauges $14.99, cards $7.99, tax $2.70 = $41.37

Hose and valve I had laying around.

Hope this gives you some ideas.

The only problem is not being able the test while filling.

Scott

The test disk would not turn back to blue.

Put the disk in my toaster oven at 325 and it started to change back to blue.

Think the temp was a little high because it then turned brown.

Checking the August site for a new disk $13.95, shipping $20.25 was more than I was going to spend

on something that might not be working.

I have setup something different, a 2 1/2" X 10" clear filter housing with 1/2" openings, 2 digital temp and moisture gauges, humidity indicator cards, a 1/2" tank valve and a piece of tubing.

I put the valve on the outlet side of the housing and the tube on the inside the route the air to the bottom of housing.

Put both gauges and a card inside, close it up and hook it to the fill hose.

Seems to work fine, ran for 3 min., the gauges dropped to 10 % there lowest reading and the card was all blue 10% lowest reading.

Housing $15.69, gauges $14.99, cards $7.99, tax $2.70 = $41.37

Hose and valve I had laying around.

Hope this gives you some ideas.

The only problem is not being able the test while filling.

Scott

You do not have the required permissions to view the files attached to this post.

- SurfLung

- Master Diver

- Posts: 1808

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Alkin = Bauer Filter

I like that system... Especially that it RESPONDS directly when you test it. If I may ask, where did you get the moisture cards and meters?

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- 2THDIVR

- Master Diver

- Posts: 144

- Joined: Sat Jan 02, 2010 4:01 pm

- First Name: Scott

- Location: Venice,FL

Re: Alkin = Bauer Filter

They were all purchased on Amazon

Hope the links work.

Housing

Hydronixhttps://www.amazon.com/dp/B01CFOGDZO?psc=1&ref= ... ct_details HF3-10CLBK12, 10" Clear Housing with Black Rib Cap For RO & Filtration Systems, 1/2" Ports

https://www.amazon.com/dp/B01CFOGDZO?ps ... ct_details

Gauges

ThermoPro TP157 2 Pack Hygrometer Indoor Thermometer for Home, Room Thermometer Humidity Meter with Temperature Humidity Sensor for Greenhouse Baby Room Office

https://www.amazon.com/dp/B09681PM6P?re ... tails&th=1

Moisture cards

Dry & Dry Premium Humidity Indicator Cards 20 Pack(Reusable) - 10-60% 6 Spot(20 Cards)

https://www.amazon.com/dp/B01974FX42?ps ... ct_details

Hope the links work.

Housing

Hydronixhttps://www.amazon.com/dp/B01CFOGDZO?psc=1&ref= ... ct_details HF3-10CLBK12, 10" Clear Housing with Black Rib Cap For RO & Filtration Systems, 1/2" Ports

https://www.amazon.com/dp/B01CFOGDZO?ps ... ct_details

Gauges

ThermoPro TP157 2 Pack Hygrometer Indoor Thermometer for Home, Room Thermometer Humidity Meter with Temperature Humidity Sensor for Greenhouse Baby Room Office

https://www.amazon.com/dp/B09681PM6P?re ... tails&th=1

Moisture cards

Dry & Dry Premium Humidity Indicator Cards 20 Pack(Reusable) - 10-60% 6 Spot(20 Cards)

https://www.amazon.com/dp/B01974FX42?ps ... ct_details

- SurfLung

- Master Diver

- Posts: 1808

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Alkin = Bauer Filter

Thanks ToothDiver! I just ordered those items.

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- antique diver

- Master Diver

- Posts: 2217

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Alkin = Bauer Filter

Hey Scott,

This looks like a great way to check moisture levels, and economical as well. Good Job!

This looks like a great way to check moisture levels, and economical as well. Good Job!

The older I get the better I was.

- luis

- VDH Moderator

- Posts: 1751

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Alkin = Bauer Filter

Hi Scott

In general, I like the concept of testing the compressed air by taking a small sample into a lower pressure or ambient pressure container. I do this to take air samples, to check for carbon monoxide when I travel.

But I am under the impression that this humidity meter doesn’t read low enough to provide useful information. Please correct me if I am wrong.

The humidity level that I like to see out of my compressed air should be in a dew point of about -40F when it is brought back to ambient pressure. If I am assuming an ambient temperature of about 65F, then the relative humidity of the air coming out of my cylinder should be about 0.9%.

You can use this website to calculate from dew point to relative humidity (at ambient pressure):

https://bmcnoldy.earth.miami.edu/Humidity.html

In other words, you need a meter that reads ultra-low humidity accurately, with readings of dew point lower than -20F and or relative humidity lower than 2% accurately.

I found this humidity sensor that reads dew point down to -22F. I think that is barely good enough to get you in the ballpark, but I would like to find something that measure even lower. This meter is $36, which is not bad.

https://www.amazon.com/dp/B01CY29RCI/?c ... _lig_dp_it

I would recommend at least using this meter with your method. I may try that.

Notice that this meter and many others will specify a relative humidity measuring range from 0% to 100%, but then they have a accuracy of + or – 2% RH. I don’t think that is accurately enough if you are trying to detect a relative humidity under 1%.

A relative humidity of 10% at a temperature of 65F produces a dew point of 7F. That seems very dry, but it is not dry enough for compressed air.

The reason those disc that read at 10% are somewhat useful in the sight-glass is because they are testing high pressure air. The relative humidity changes with air pressure, but I have not found good data to correlate RH (or dew point) as a function of pressure.

The dew point goes up with pressure and that is why you need extremely dry air to keep from getting condensation inside your steel cylinders and avoiding rust, etc.

An interesting piece of trivia: Fire fighters in the Navy are particularly concern about moisture in the compressed breathing air, when fighting fires in cold temperatures. They are now running SCBA with cylinders at much higher pressures than our SCUBA cylinders, and much higher risk of moisture freezing in the regulator first-stage.

In general, I like the concept of testing the compressed air by taking a small sample into a lower pressure or ambient pressure container. I do this to take air samples, to check for carbon monoxide when I travel.

But I am under the impression that this humidity meter doesn’t read low enough to provide useful information. Please correct me if I am wrong.

The humidity level that I like to see out of my compressed air should be in a dew point of about -40F when it is brought back to ambient pressure. If I am assuming an ambient temperature of about 65F, then the relative humidity of the air coming out of my cylinder should be about 0.9%.

You can use this website to calculate from dew point to relative humidity (at ambient pressure):

https://bmcnoldy.earth.miami.edu/Humidity.html

In other words, you need a meter that reads ultra-low humidity accurately, with readings of dew point lower than -20F and or relative humidity lower than 2% accurately.

I found this humidity sensor that reads dew point down to -22F. I think that is barely good enough to get you in the ballpark, but I would like to find something that measure even lower. This meter is $36, which is not bad.

https://www.amazon.com/dp/B01CY29RCI/?c ... _lig_dp_it

I would recommend at least using this meter with your method. I may try that.

Notice that this meter and many others will specify a relative humidity measuring range from 0% to 100%, but then they have a accuracy of + or – 2% RH. I don’t think that is accurately enough if you are trying to detect a relative humidity under 1%.

A relative humidity of 10% at a temperature of 65F produces a dew point of 7F. That seems very dry, but it is not dry enough for compressed air.

The reason those disc that read at 10% are somewhat useful in the sight-glass is because they are testing high pressure air. The relative humidity changes with air pressure, but I have not found good data to correlate RH (or dew point) as a function of pressure.

The dew point goes up with pressure and that is why you need extremely dry air to keep from getting condensation inside your steel cylinders and avoiding rust, etc.

An interesting piece of trivia: Fire fighters in the Navy are particularly concern about moisture in the compressed breathing air, when fighting fires in cold temperatures. They are now running SCBA with cylinders at much higher pressures than our SCUBA cylinders, and much higher risk of moisture freezing in the regulator first-stage.

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

- 2THDIVR

- Master Diver

- Posts: 144

- Joined: Sat Jan 02, 2010 4:01 pm

- First Name: Scott

- Location: Venice,FL

Re: Alkin = Bauer Filter

Luis,

I picked up this moisture checker.

https://www.amazon.com/dp/B01FGV28E8?re ... tails&th=1

Ran compressor this afternoon,

Moisture card was all blue

Old moisture gauge read 10%

New gauge read .16

Think I'm good.

Thanks for the input.

Scott

I picked up this moisture checker.

https://www.amazon.com/dp/B01FGV28E8?re ... tails&th=1

Ran compressor this afternoon,

Moisture card was all blue

Old moisture gauge read 10%

New gauge read .16

Think I'm good.

Thanks for the input.

Scott

- luis

- VDH Moderator

- Posts: 1751

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Alkin = Bauer Filter

Hi Scott,

That is interesting. That one shows a dew point of -58F, which should be in the rage on interest. I still wonder how accurate they are at the ultra-low humidity we are interested in.

The other thing to keep in mind is to do a good flushing with your dry air. Moisture will probably leak back into your dry container fairly quickly.

So, the coincidence is that I also wanted to try this approach and I also ordered a unit from Amazon and received it today. The unit I got is this one:

https://www.amazon.com/dp/B0BD7NQG2J?ps ... ct_details

It also advertises a dew point range down to -58F. It specifies an accuracy of (+/ –) 3F at the ultra-low range, which sounds good enough to me. But then, what I find puzzling is that in the relative humidity scale it specifies (+/ –) 4% in the ultra-low range, which is not very good and I don’t know how that is consistent with the dew-point accuracy.

Oh well, I am going to try it and see if I get at least a reasonably indication of very dry air. It is not a big investment and it is not a bad instrument to have.

Good luck

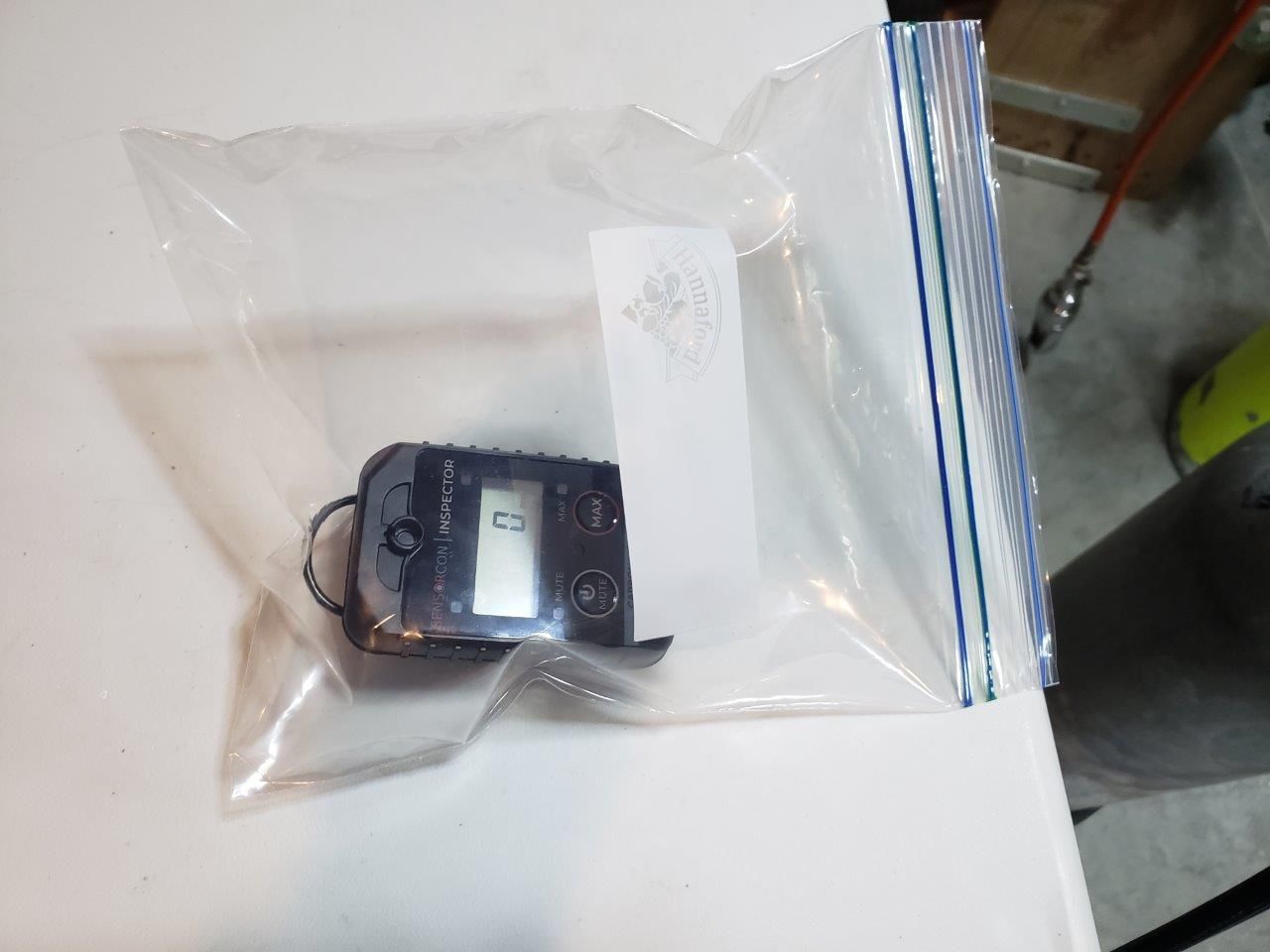

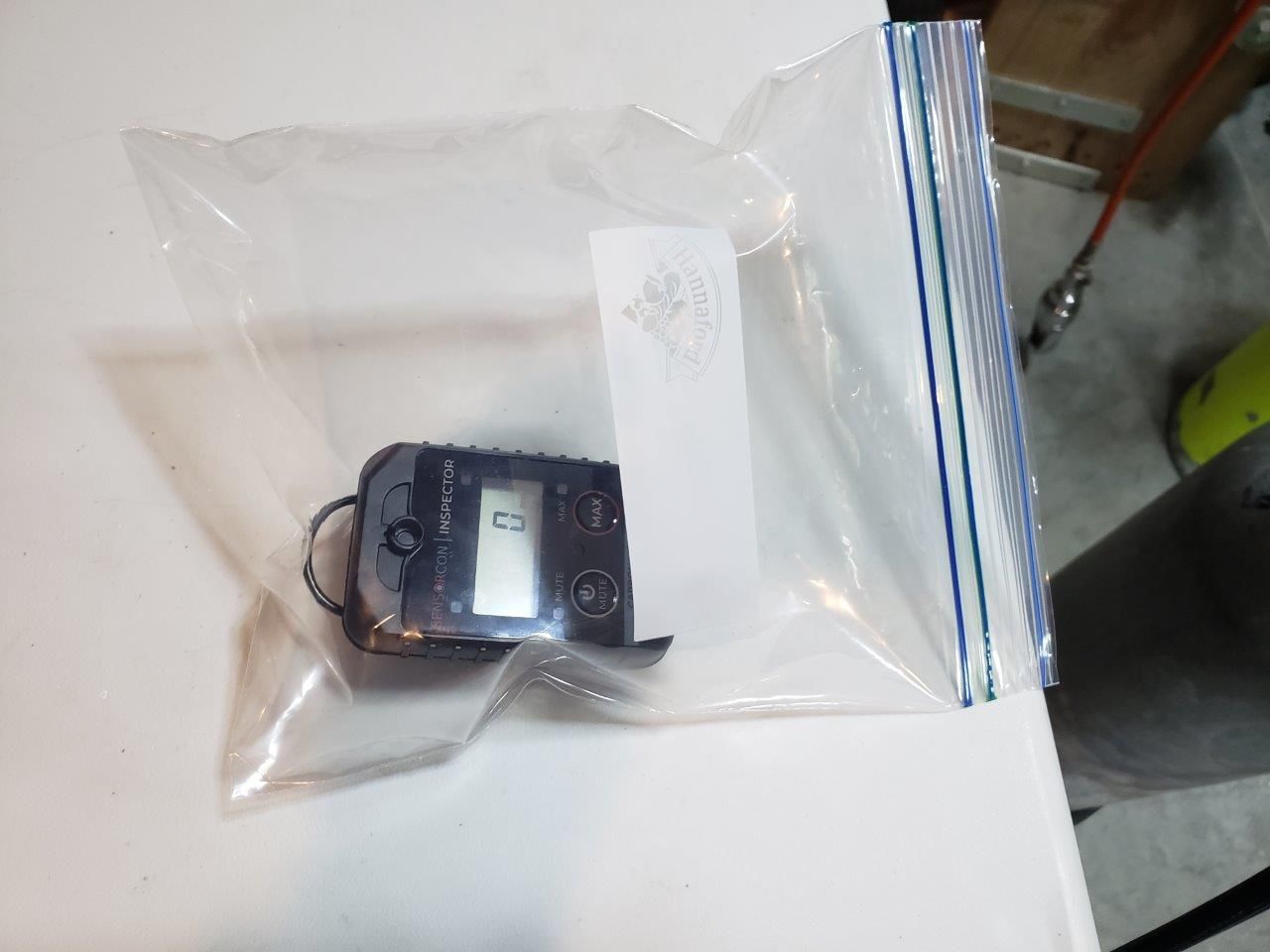

Co monitor

I have been testing for carbon monoxide (CO) in compress air using a similar ambient pressure technique. But measuring for CO is much easier, because there should not be any in or around the area. I just use a Ziplock bag and an industrial CO monitor. It is very portable approach, so I have been doing it not only with my compressor, but when I travel, I take an occasional sample of the air or Nitrox that we are breathing.

Here is the type of CO monitor I use:

https://www.amazon.com/Sensorcon-Inspec ... hdGY&psc=1

Here are pictures of how I use the CO monitor. Again checking for CO is a lot easier that moisture.

That is interesting. That one shows a dew point of -58F, which should be in the rage on interest. I still wonder how accurate they are at the ultra-low humidity we are interested in.

The other thing to keep in mind is to do a good flushing with your dry air. Moisture will probably leak back into your dry container fairly quickly.

So, the coincidence is that I also wanted to try this approach and I also ordered a unit from Amazon and received it today. The unit I got is this one:

https://www.amazon.com/dp/B0BD7NQG2J?ps ... ct_details

It also advertises a dew point range down to -58F. It specifies an accuracy of (+/ –) 3F at the ultra-low range, which sounds good enough to me. But then, what I find puzzling is that in the relative humidity scale it specifies (+/ –) 4% in the ultra-low range, which is not very good and I don’t know how that is consistent with the dew-point accuracy.

Oh well, I am going to try it and see if I get at least a reasonably indication of very dry air. It is not a big investment and it is not a bad instrument to have.

Good luck

Co monitor

I have been testing for carbon monoxide (CO) in compress air using a similar ambient pressure technique. But measuring for CO is much easier, because there should not be any in or around the area. I just use a Ziplock bag and an industrial CO monitor. It is very portable approach, so I have been doing it not only with my compressor, but when I travel, I take an occasional sample of the air or Nitrox that we are breathing.

Here is the type of CO monitor I use:

https://www.amazon.com/Sensorcon-Inspec ... hdGY&psc=1

Here are pictures of how I use the CO monitor. Again checking for CO is a lot easier that moisture.

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

- SurfLung

- Master Diver

- Posts: 1808

- Joined: Sat Jan 01, 2011 2:03 pm

- First Name: Eben

- Location: Alexandria, MN

- Contact: Website

Re: Alkin = Bauer Filter

Just What I Needed...

Thanks 2thdiver for such an inexpensive, simple and reliable solution. I made up a "quickly assembled" version of your moisture checking container. In place of your clear hose to carry the incoming air to the bottom, I zip tied a piece of corrugated hose from an old double hose reg. For the 1/2" NPT inlet valve I screwed in an old scuba tank post valve. And finally, I set one of the moisture level dot cards out on the deck with the battery power meter. I had to let this set for several minutes until the dots caught up with the meter and the surrounding air... Close to all of them turned pink and the moisture level agreed with the little moisture meter.

Then, I put the card into the container and turned on the Alkin W31 compressor. Holy cow! The air coming out of this compressor is so dry, it turned all of the dots back to blue in 3-5 minutes! That's just what I needed... I was looking for something to give me physical confirmation that my filter media is good or if it needs changing. This system does that decisively.

The Alkin manual says I should change the filter media every 50 hours or once a year, whichever comes first. Now, I can add... "Or, if the moisture card in the container reads 10% or higher".

Notes Worth Reading...

1. The "inlet" on the container is actually the outlet in this application.

2. If you use a tank valve for the inlet, remember to keep it open so as not to build pressure.

Other Uses...

- Considering that the viewport device did NOT give me reliable performance with the moisture disk, I don't feel it will do any better with the little CO detection disk. On the other hand, a CO detector (like Luis') will fit in this container easily.

Thanks 2thdiver for such an inexpensive, simple and reliable solution. I made up a "quickly assembled" version of your moisture checking container. In place of your clear hose to carry the incoming air to the bottom, I zip tied a piece of corrugated hose from an old double hose reg. For the 1/2" NPT inlet valve I screwed in an old scuba tank post valve. And finally, I set one of the moisture level dot cards out on the deck with the battery power meter. I had to let this set for several minutes until the dots caught up with the meter and the surrounding air... Close to all of them turned pink and the moisture level agreed with the little moisture meter.

Then, I put the card into the container and turned on the Alkin W31 compressor. Holy cow! The air coming out of this compressor is so dry, it turned all of the dots back to blue in 3-5 minutes! That's just what I needed... I was looking for something to give me physical confirmation that my filter media is good or if it needs changing. This system does that decisively.

The Alkin manual says I should change the filter media every 50 hours or once a year, whichever comes first. Now, I can add... "Or, if the moisture card in the container reads 10% or higher".

Notes Worth Reading...

1. The "inlet" on the container is actually the outlet in this application.

2. If you use a tank valve for the inlet, remember to keep it open so as not to build pressure.

Other Uses...

- Considering that the viewport device did NOT give me reliable performance with the moisture disk, I don't feel it will do any better with the little CO detection disk. On the other hand, a CO detector (like Luis') will fit in this container easily.

SurfLung

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

The Freedom and Simplicity of Vintage Equipment and

Vintage Diving Technique are Why I Got Back Into Diving.

- luis

- VDH Moderator

- Posts: 1751

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Alkin = Bauer Filter

This is what I call dry air.

The bottom reading on the meter is dew point of -44.6F and the middle number is relative humidity of 1.0 %

The air temperature inside the case in shown on the top reading (51.4F). The temperature dropped as I was flushing the case.

This is just coming out of a scuba tank that I filled. I used an LP inflator hose out of one of my utility Conshelf 1st stages.

I added an exhaust valve on the back of the case so that I can flush the inside of the case with a constant flow. Humidity leaks back in fairly fast when I shot off the air supply.

The numbers tend to agree with what you can calculate on this web site:

https://bmcnoldy.earth.miami.edu/Humidity.html

At the lowest dew point the relative humidity was off by 0.1%. Which is not bad.

The absolute humidity in my air calculates to 6.2E-6 Lb/ cu ft or an actual vapor pressure of 1.87E-3 psi. That is 76ppm by mass, not bad.

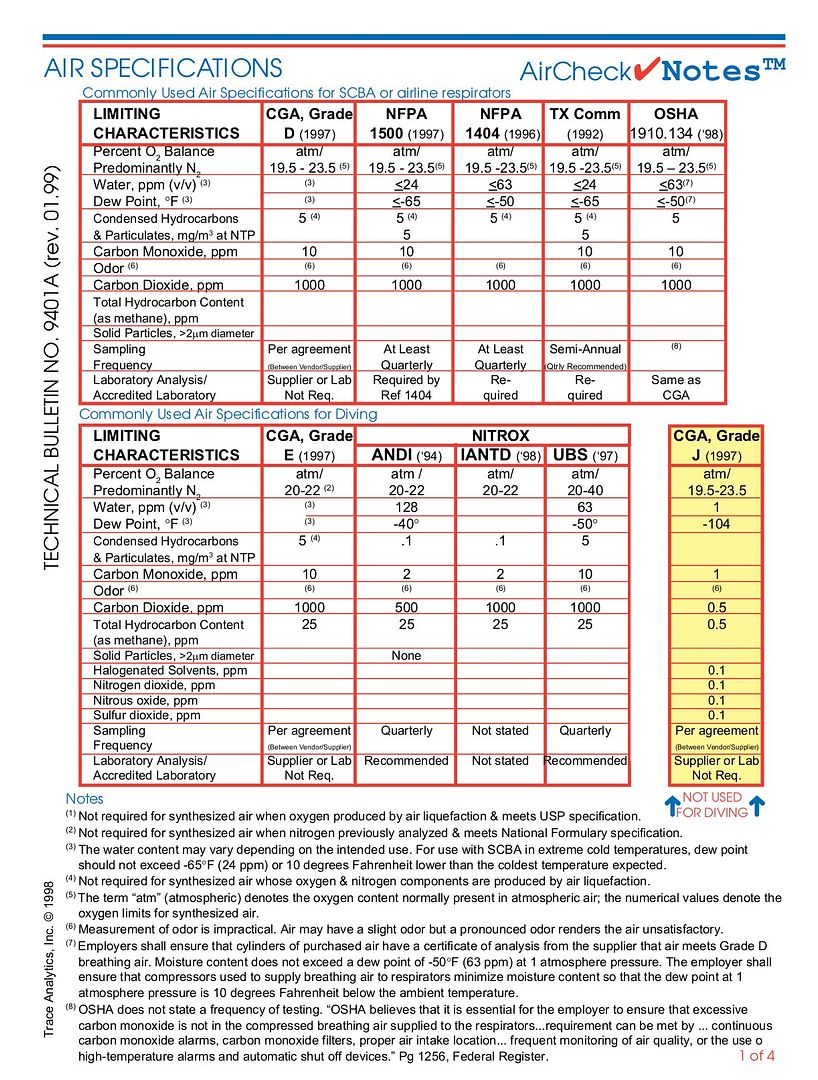

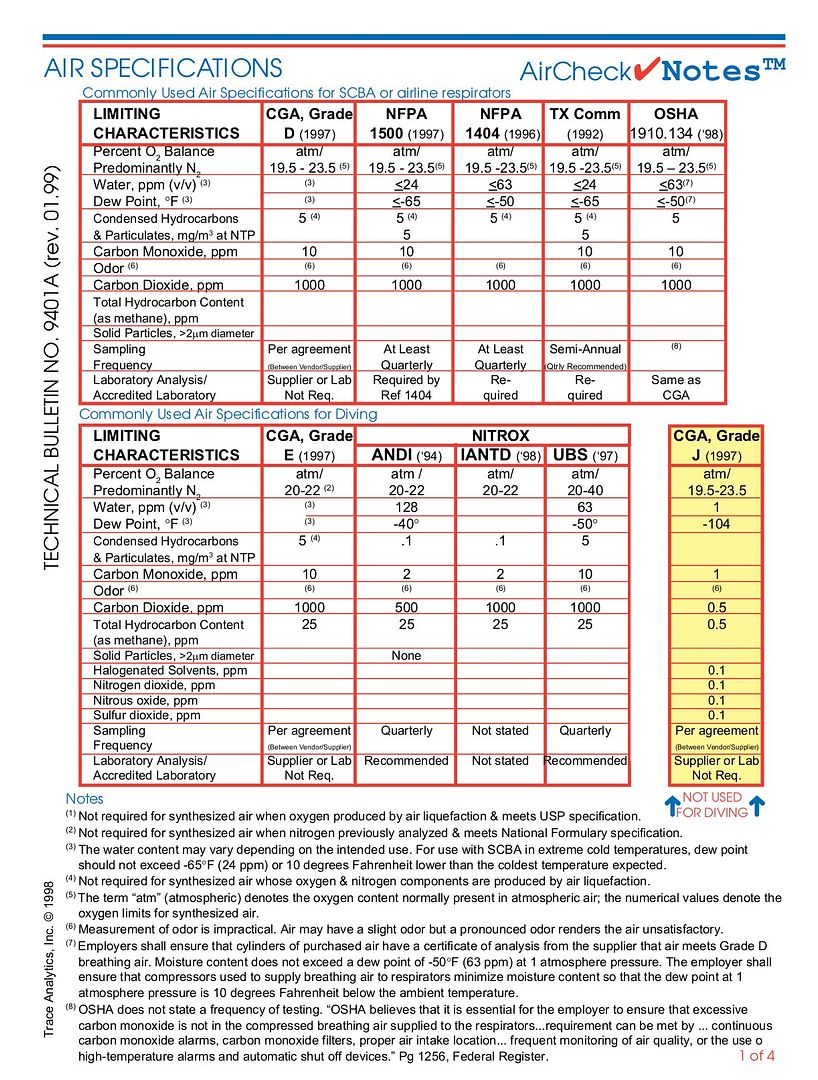

Here are air specifications.

The bottom reading on the meter is dew point of -44.6F and the middle number is relative humidity of 1.0 %

The air temperature inside the case in shown on the top reading (51.4F). The temperature dropped as I was flushing the case.

This is just coming out of a scuba tank that I filled. I used an LP inflator hose out of one of my utility Conshelf 1st stages.

I added an exhaust valve on the back of the case so that I can flush the inside of the case with a constant flow. Humidity leaks back in fairly fast when I shot off the air supply.

The numbers tend to agree with what you can calculate on this web site:

https://bmcnoldy.earth.miami.edu/Humidity.html

At the lowest dew point the relative humidity was off by 0.1%. Which is not bad.

The absolute humidity in my air calculates to 6.2E-6 Lb/ cu ft or an actual vapor pressure of 1.87E-3 psi. That is 76ppm by mass, not bad.

Here are air specifications.

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

- antique diver

- Master Diver

- Posts: 2217

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Alkin = Bauer Filter

I like the electronic solution, and plan to go with some variation of it.

Meanwhile, just for the fun of it, I coupled up a few odds and ends to make this mechanical tester to connect in my HP fill system. It can remain in place when actually filling, and is removable with a quick-disconnect to store the assembly in a dry place.

Added a Tee and line valve leading to a simple regulator that was initially used in a OMS Oxygen test rig. I can control the airflow volume at the clear plastic flow gauge. The original "floating" ball was removed and replaced with the blue object that floats in response to the adjusted air flow. It's a perforated capsule containing moisture sensitive granules that are blue when dry and lose color when the air begins to get too moist. Just like the blue paper strips in some filter cartridges. I will have to experiment to determine optimum air flow.

Here's the slightly Revised working model, and is removed from the compressor for storage in a dry box:

I haven't tried it out yet, and it may need some pressure or flow rate adjustments... or it may just be a total flop!

Meanwhile, just for the fun of it, I coupled up a few odds and ends to make this mechanical tester to connect in my HP fill system. It can remain in place when actually filling, and is removable with a quick-disconnect to store the assembly in a dry place.

Added a Tee and line valve leading to a simple regulator that was initially used in a OMS Oxygen test rig. I can control the airflow volume at the clear plastic flow gauge. The original "floating" ball was removed and replaced with the blue object that floats in response to the adjusted air flow. It's a perforated capsule containing moisture sensitive granules that are blue when dry and lose color when the air begins to get too moist. Just like the blue paper strips in some filter cartridges. I will have to experiment to determine optimum air flow.

Here's the slightly Revised working model, and is removed from the compressor for storage in a dry box:

I haven't tried it out yet, and it may need some pressure or flow rate adjustments... or it may just be a total flop!

The older I get the better I was.

- luis

- VDH Moderator

- Posts: 1751

- Joined: Thu Jun 30, 2005 9:28 pm

- First Name: Luis

- Location: Maine

Re: Alkin = Bauer Filter

It is important to keep in mind that relative humidity (RH) and dew point (DP) change with pressure.

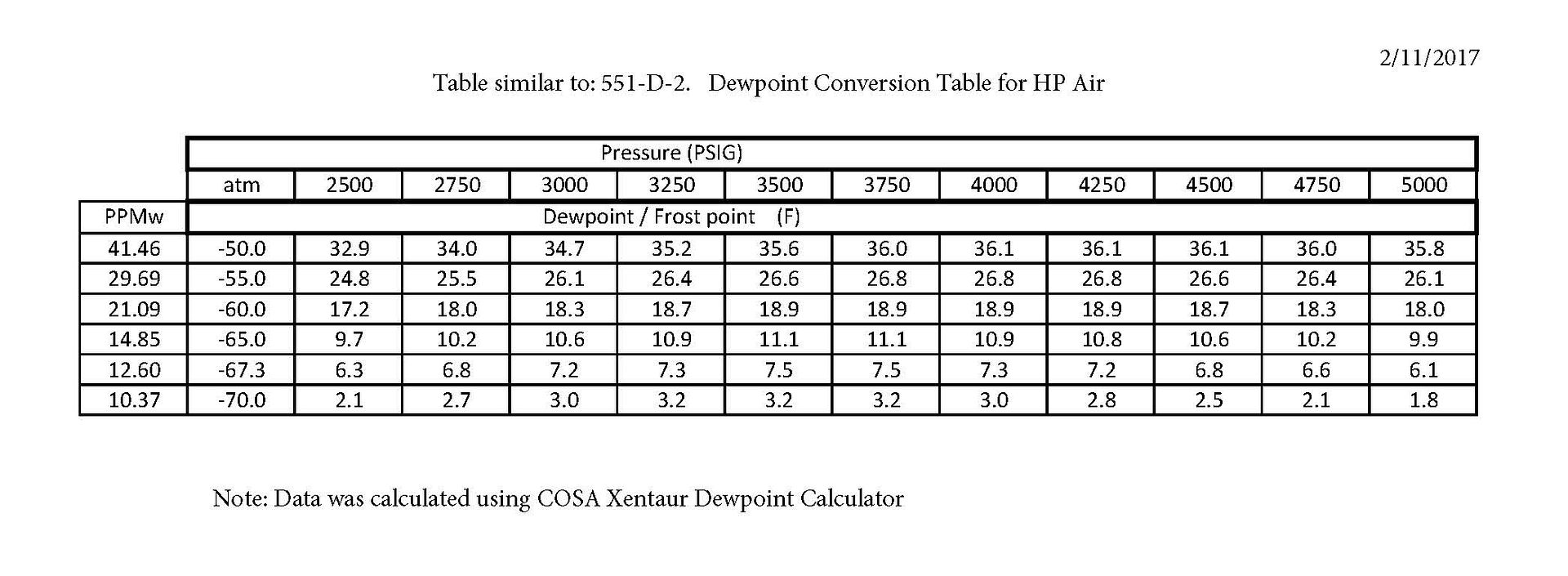

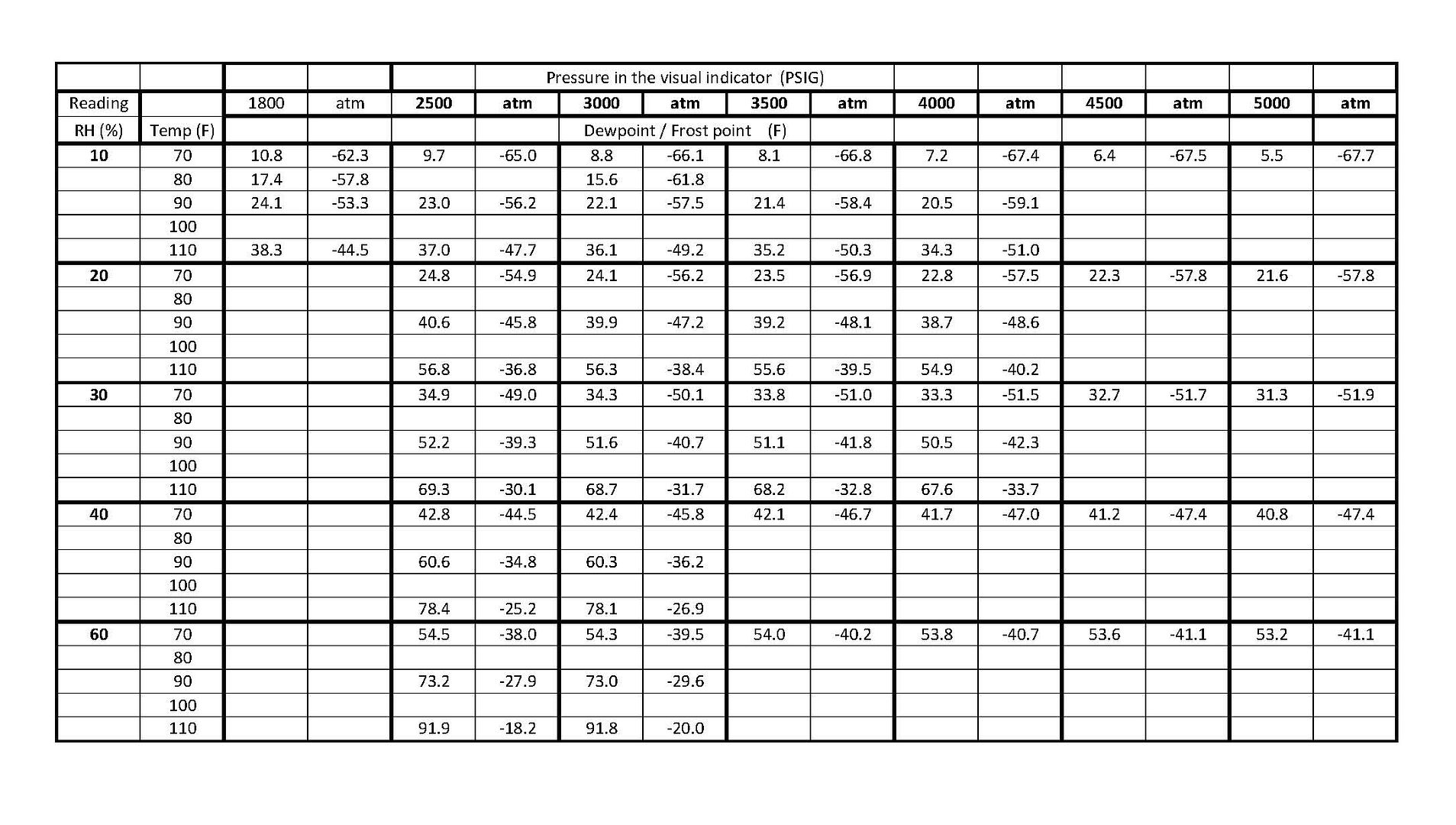

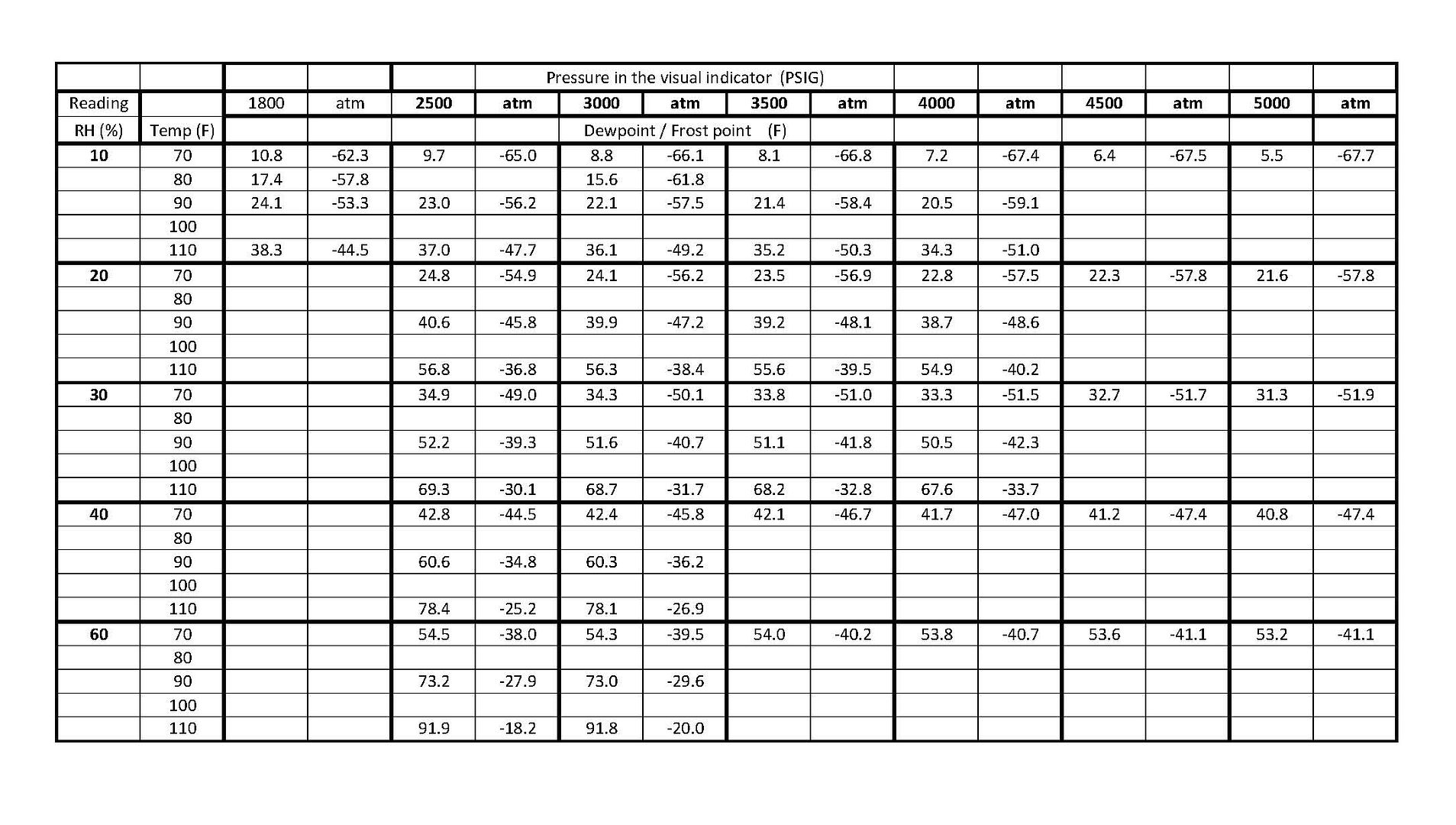

The measurement of DP of about -45F (RH = 1.0 %) at an ambient air temp of about 51F is data taken at 1 atmosphere (ATM). The 1.0% relative humidity becomes about 40% RH at high pressure (at about 2500 psi). That is why we can use those pie discs (that read 10%, 20%, 30%) inside the high pressure windows.

The 10% relative humidity indicator (at 2500 psi) translates to a 1 ATM dew point of about -65 F or a RH of about 0.23% at about 60F, actual air temperature. That ultra-low humidity is extremely hard to measure at 1 atmosphere. My electronic instrument is not capable of measuring that low, and to be honest, at RH of around 1% it is probably not that accurate, but it is a good indicator.

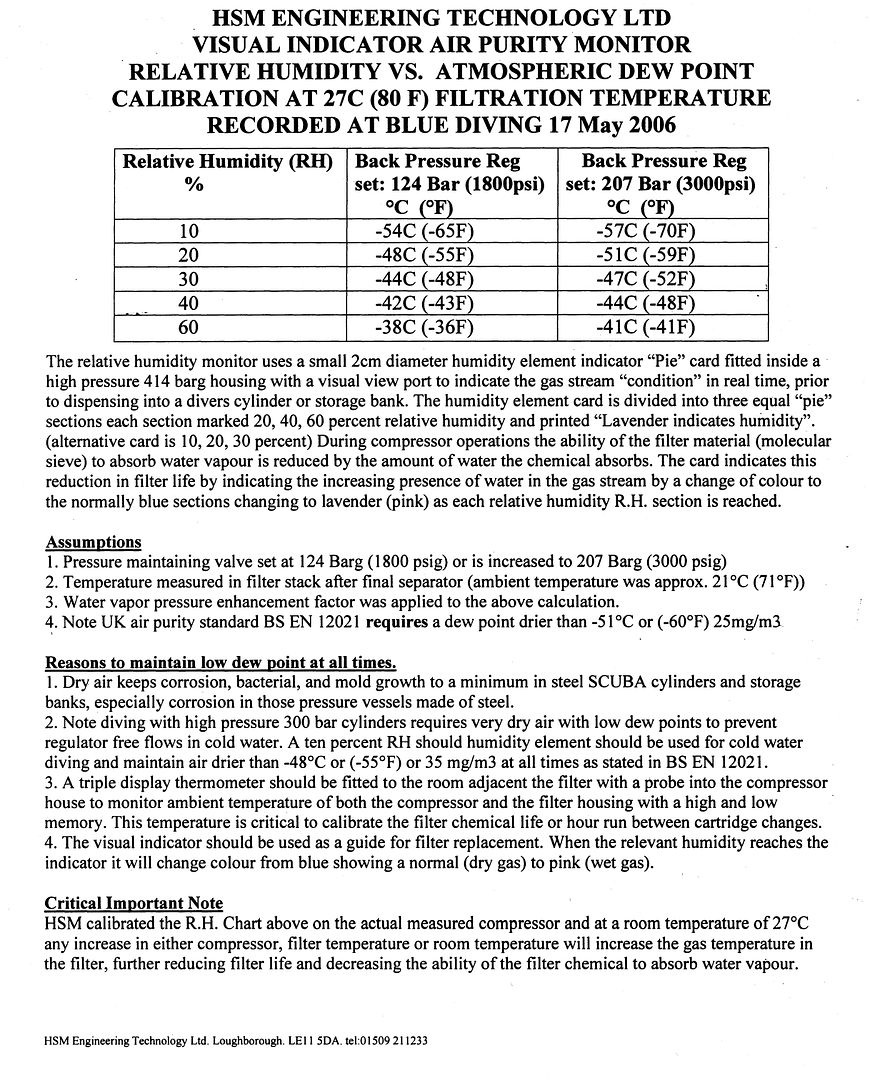

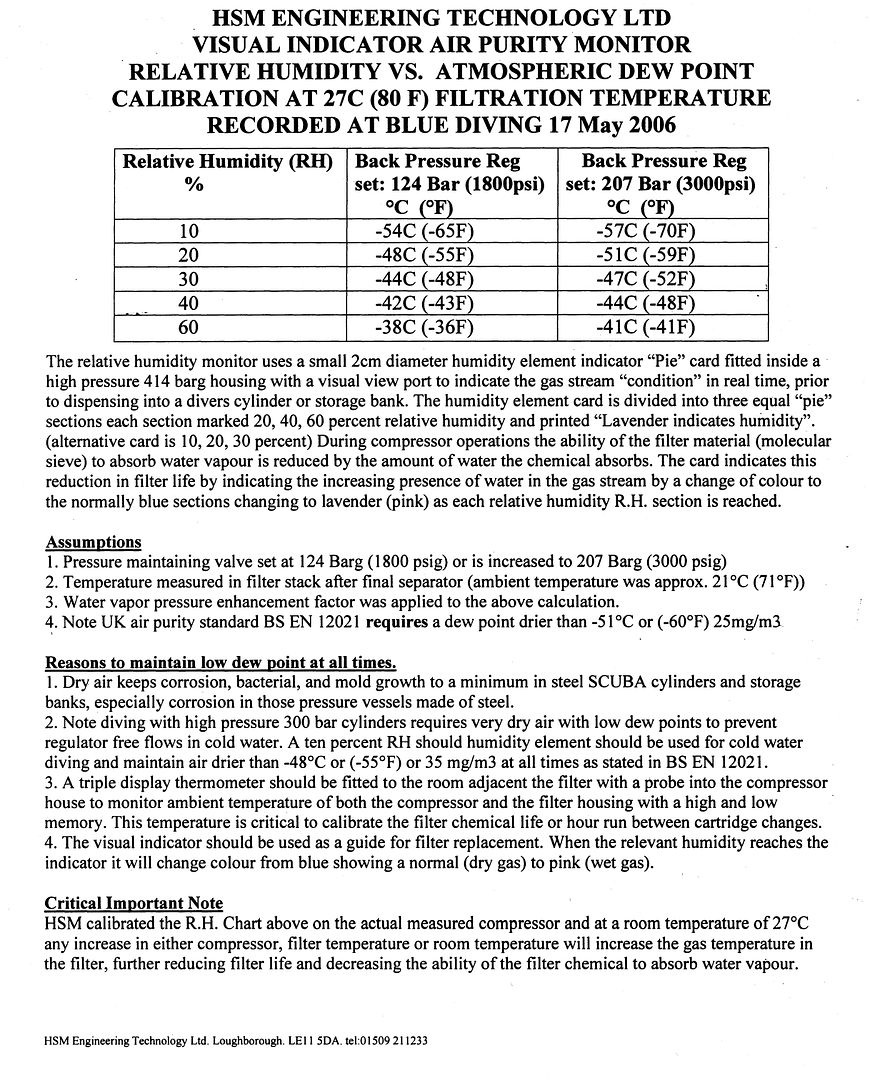

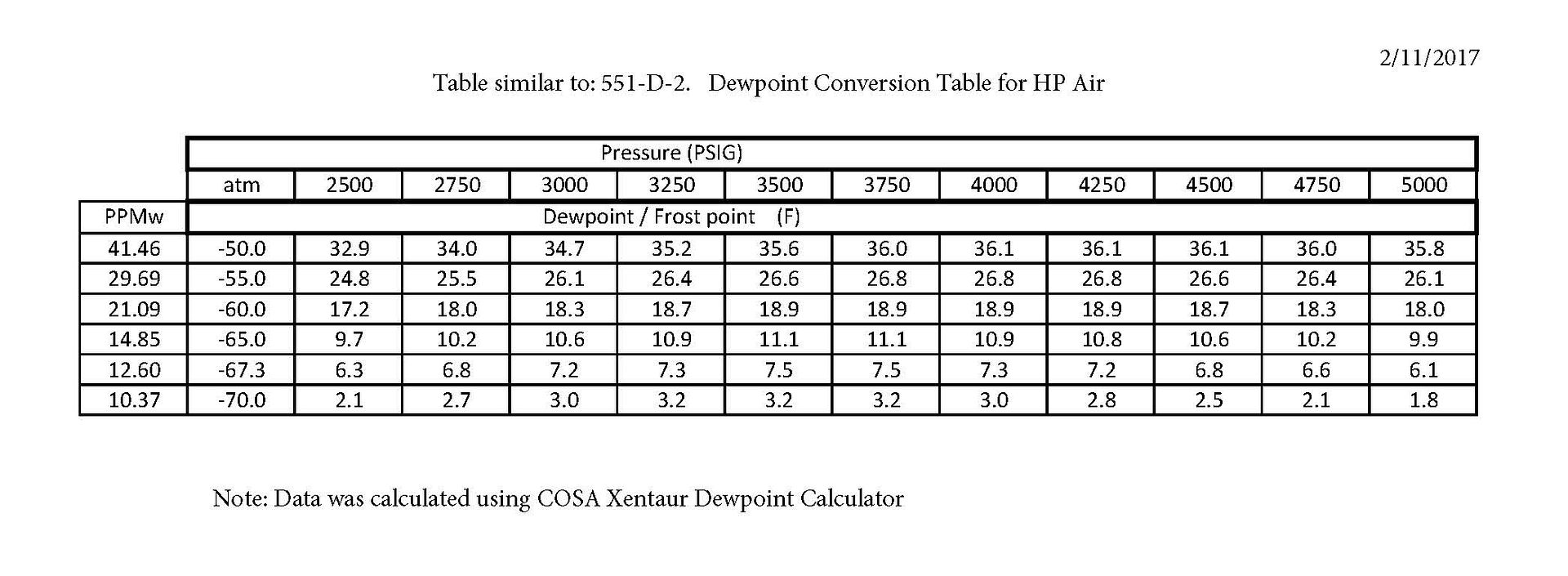

Here are some tables that can be useful, but I will admit that it can also be confusing.

This first document is very interesting in describing the high pressure visual indicators.

_________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

The measurement of DP of about -45F (RH = 1.0 %) at an ambient air temp of about 51F is data taken at 1 atmosphere (ATM). The 1.0% relative humidity becomes about 40% RH at high pressure (at about 2500 psi). That is why we can use those pie discs (that read 10%, 20%, 30%) inside the high pressure windows.

The 10% relative humidity indicator (at 2500 psi) translates to a 1 ATM dew point of about -65 F or a RH of about 0.23% at about 60F, actual air temperature. That ultra-low humidity is extremely hard to measure at 1 atmosphere. My electronic instrument is not capable of measuring that low, and to be honest, at RH of around 1% it is probably not that accurate, but it is a good indicator.

Here are some tables that can be useful, but I will admit that it can also be confusing.

This first document is very interesting in describing the high pressure visual indicators.

_________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________

Luis

Buceador con escafandra autónoma clásica.

Buceador con escafandra autónoma clásica.

Who is online

Users browsing this forum: No registered users and 10 guests