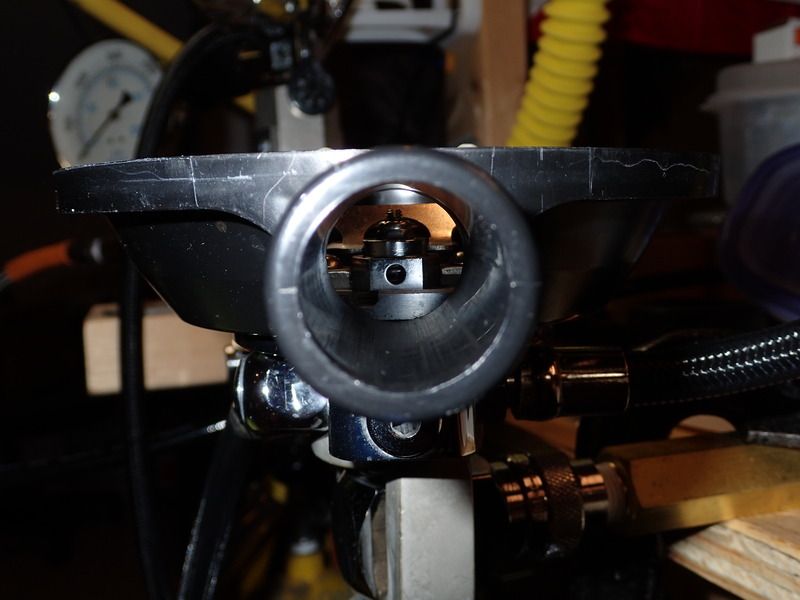

DSV (Dive Surface Valve) style of mouthpiece

Features:

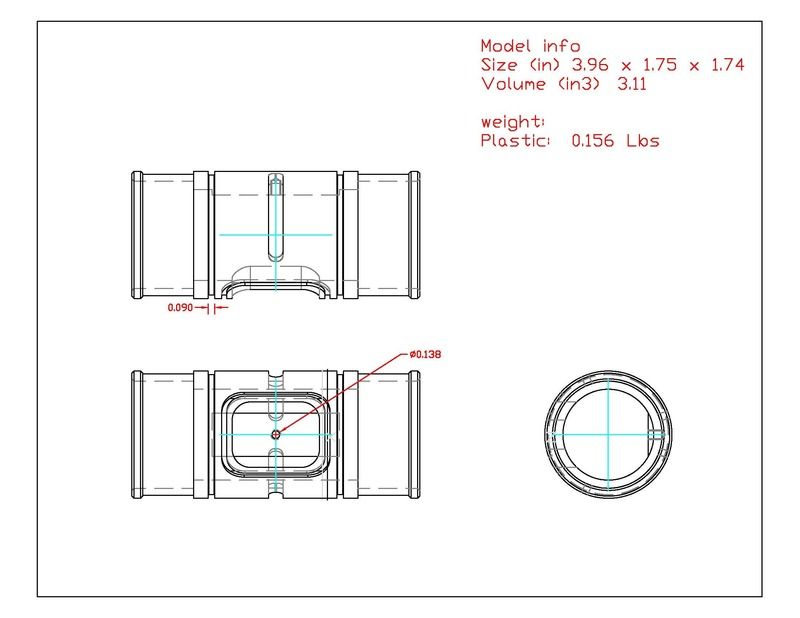

1) Simple design with minimal number of parts to increase reliability and keep production cost down.

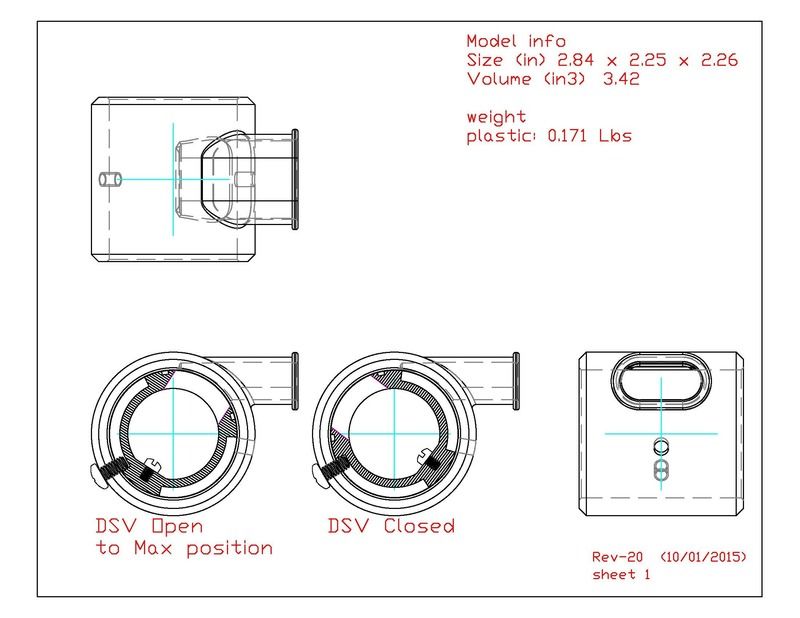

2) Closing feature is accomplish by rotating hose / hose clamp assembly. No lever sticking out of the front of the assembly.

3) There is a removable mechanical stop that limits the rotation and gives positive feedback that the DSV is open or closed. The stop also keeps the two cylinder in alignment. The stop is removed in order to disassemble the DSV.

4) Water in the mouthpiece byte tube can be purged before opening mouthpiece. This keeps the loop completely dry.

5) There are traditional check valves (inlet and outlet) on both sides of the mouthpiece, but if the diver purges the little water inside the byte tube, there will never be any water entering either hose that will need purging. Purging by just blowing (or raising the MP above the can) is always possible as with a traditional MP.

6) Mouthpiece was tested as completely water tight. Test showed that after 25 consecutive dives, regulator and inlet air hose were totally dry.

7) There is no special maintenance required for the mouthpiece and since the regulator will be kept dryer, the maintenance on it will be reduced.

8 ) The mouthpiece has five O-rings:

a) The two on the wagon wheel valves are static O-ring and will probably outlast the silicone mushroom valve.

b) There are two radial O-ring that provide a controlled amount of friction to the DSV rotation (They are not sealing O-rings).

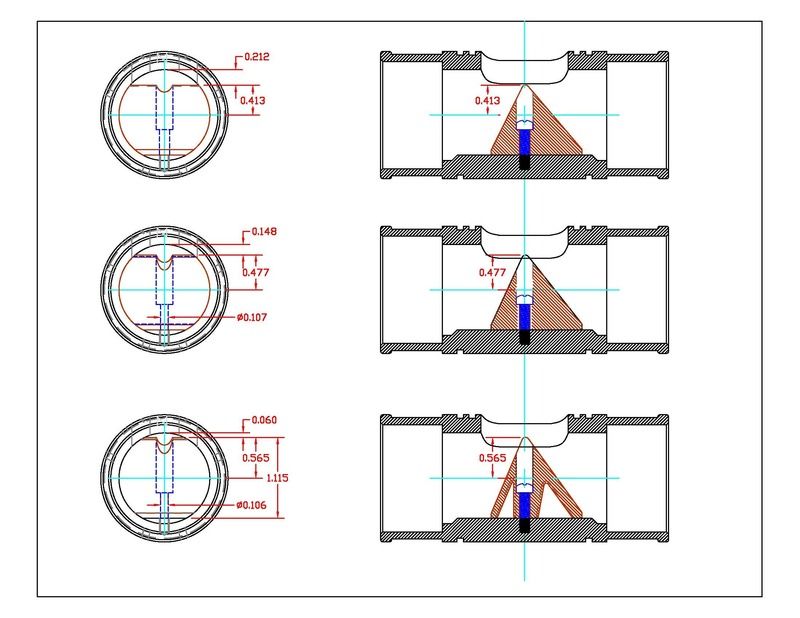

c) There is one O-ring that seals on the mouthpiece opening (or in the closed position). This O-ring can be easily inspected while rotating the DSV and it is easily replaced. The O-ring is captured, it only sees about 10% to 15% compression during operation, and has smooth surface to slide into with a nice rounded edge.

9) Air passage in mouthpiece is very large and optimized to minimize flow resistance.

10) Flow diverter provides smooth flow transition into and out of divers mouth.

The inlet and outlet flow diverter ramp angle are different. They are designed for the difference in the flow velocity (inlet flow with venturi assist versus the slower outlet flow).

11) Flow diverter is optimized to take full advantage of Argonaut Kraken maximum possible venturi flow. See note.

12) Several flow diverter were designed and tested. The attached sketch shows three of the flow diverters tested. They have different height and flow angle. The 2 dimensional drawing is a bit misleading about the true flow path areas, but it should give an idea of the design.

Note: The Argonaut Kraken was specifically design to have a very adjustable cracking effort and venturi flow.

The lowest reasonable cracking effort is limited by the radius of the exhaust valve (about 1/2”). If the cracking effort is adjusted lower than 1/2 inWC, the regulator will tend to have a light free flow when the top edge of the exhaust is higher than the center of the diaphragm.

Without the DSV flow diverter, the amount of venturi flow adjustment in the Argonaut Kraken had to be limited to avoid the excessive flow from blowing past the mouthpiece and out the exhaust. The flow diverter in the mouthpiece was specifically designed to take advantage of the strong venturi flow the Argonaut can be adjusted to. No excessive air is allowed to blow-by past the mouthpiece. All the air is directed towards the diver. Once flow is initiated, only the air used by the diver will be supplied with minimum inhalation effort (with no wasted air out the exhaust).

The sketch below shows three different diverter that were analyzed and 3D model prototypes were tested.

I will be updating this page in the near future.