Ed, I have never seen one with the holes through the sides, and can see no reason for them. I was surprised to see how deep the nylon goes, and that leaves a lot of room for resurfacing used seats... but may need to renew the little dimple as well if you take off too much material.

It's the same seats that were used in all of the double hose Dacors as far as I could tell, and they were also used in the Dacor 200.

I can't tell if the brass center in nylon is pressed in or part of the brass body as I had always assumed. I may have to sacrifice one to find out.

Between my seats and Herman's help, I think we will be able to get a few usable ones made up. It may take a week or two to find out, but stay in touch.

Thanks for the helpful photos.

BT

- antique diver

- Master Diver

- Posts: 2217

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Dacor HP seat problem

The older I get the better I was.

-

crimediver

- Master Diver

- Posts: 412

- Joined: Tue Jul 12, 2005 7:38 am

- Location: Richmond, Va

Re: Dacor HP seat problem

You mean like this guy:antique diver wrote:Drado, you are so lucky that you weren't looking down the bore when that thing came apart!

And don't be looking down any gun barrels either.

http://www.youtube.com/watch?v=SRIr7c35zuY

I once had a badly corroded SPG spool stick in a HP hose and vice grips did not budge it. It did crush the spool and messed it up. It would not come out even though I had it in an ultrasonic bath. It looked like it was in there to stay. I clamped the running end of the hose in a bench vise and charged the hose with 3000 psi. When the spool came out it went through the wall of my shop. Compressed air packs a punch.

- antique diver

- Master Diver

- Posts: 2217

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Dacor HP seat problem

Drado,

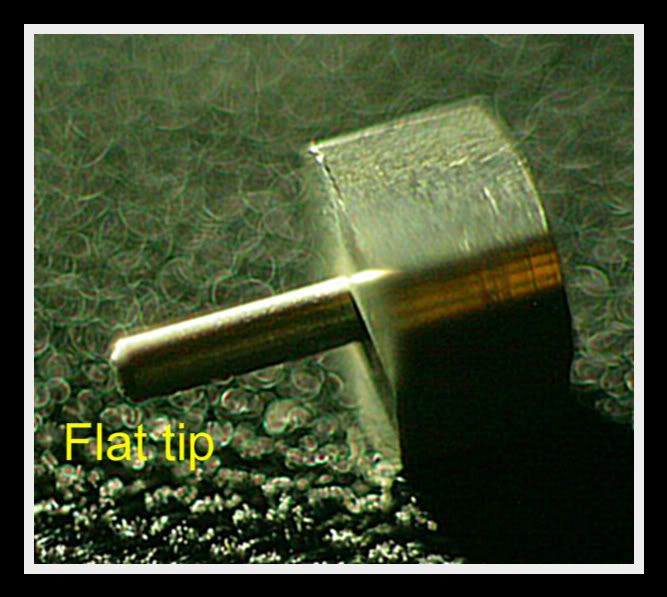

Could you confirm if the push rod on your Dacor reg has a flat tip where it contacted the hp seat? Or is it pointed?

thanks!

Could you confirm if the push rod on your Dacor reg has a flat tip where it contacted the hp seat? Or is it pointed?

thanks!

The older I get the better I was.

- Herman

- VDH Moderator

- Posts: 1317

- Joined: Thu Oct 25, 2007 1:45 pm

- Location: Raleigh NC

Re: Dacor HP seat problem

I found an old Dacor single hose that also has these type seats. This one has a dimple in the seat and when you turn it over, you can see the seat material is pressed fairly deep into the seat, note the vent hole in the second photo. You can see the seat material in the hole. I did not measure the depth of the seat material but it is aprox 1/2 way up the seat. Based on what I see, I have to believe that the pin is inserted into the material rather than the pin extending the entire length of the seat with the seat molded around it. If that is the case, these would be fairly easy to produce and/or resurface.

Herman

- Drado

- Master Diver

- Posts: 682

- Joined: Mon Feb 07, 2011 6:11 am

- First Name: Eduardo

- Location: Manila, Philippines

Re: Dacor HP seat problem

It is flat with shoulders:antique diver wrote:Drado,

Could you confirm if the push rod on your Dacor reg has a flat tip where it contacted the hp seat? Or is it pointed?

thanks!

At this point, after examining the depression in the middle under a microscope, it was too symmetric to look like something broke off. Therefore the metal center was indeed separate from the body of the seat assembly.

_______________________________

Ed

Ed

- antique diver

- Master Diver

- Posts: 2217

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Dacor HP seat problem

The seat in this photo came out of a Dacor C-3 that I rebuilt for a customer in mid-70's, and I just opened up today for the first time since that service. He never picked up the regulator, and it was never used after I serviced it... and I still have it! This was a new D1101 seat at that time, direct from Dacor.

As you can see, there is no impression or dimple for a pointed push rod, and indeed the push rod is flat on the end. The push rod is nicely supported in its position by a bushing, so no index dimple is needed to keep the rod aligned.

I have several new ones still available, but anyone that has one that is still intact should be able to resurface their old one. Drado... you need one of these.

As you can see, there is no impression or dimple for a pointed push rod, and indeed the push rod is flat on the end. The push rod is nicely supported in its position by a bushing, so no index dimple is needed to keep the rod aligned.

I have several new ones still available, but anyone that has one that is still intact should be able to resurface their old one. Drado... you need one of these.

The older I get the better I was.

- Herman

- VDH Moderator

- Posts: 1317

- Joined: Thu Oct 25, 2007 1:45 pm

- Location: Raleigh NC

Re: Dacor HP seat problem

Seems there were a couple of versions, some with dimples and others without....how do you want the ones you send me done??

Here is a before, flattened and finally dimpled versions of the ones you sent me. As thick as the material is, resurfacing it multiple times seems very possible and since the pin seems to be inserted into the nylon, I suspect they could be reproduced easily. As you can see from the photo, QC did not seem to be too important, note the various shapes of the side angles.

Here is a before, flattened and finally dimpled versions of the ones you sent me. As thick as the material is, resurfacing it multiple times seems very possible and since the pin seems to be inserted into the nylon, I suspect they could be reproduced easily. As you can see from the photo, QC did not seem to be too important, note the various shapes of the side angles.

Herman

- antique diver

- Master Diver

- Posts: 2217

- Joined: Sun Dec 10, 2006 12:50 pm

- First Name: Bill

- Location: North-Central Texas

Re: Dacor HP seat problem

Herman, I agree that QC was lax... otherwise I wouldn't have found 6 new ones at one time that were sent out with the raised bump, basically unfinished.

You keep your choice of the best one of the bunch for your regulator, and I'd like one with dimple and one flat just to cover all the bases... if that sounds fair to you. The nylon is so deep that I wouldn't worry at all about taking enough material off to eliminate the dimple if I had to have another flat one.

Thanks for the help!

Bill

You keep your choice of the best one of the bunch for your regulator, and I'd like one with dimple and one flat just to cover all the bases... if that sounds fair to you. The nylon is so deep that I wouldn't worry at all about taking enough material off to eliminate the dimple if I had to have another flat one.

Thanks for the help!

Bill

The older I get the better I was.

- Drado

- Master Diver

- Posts: 682

- Joined: Mon Feb 07, 2011 6:11 am

- First Name: Eduardo

- Location: Manila, Philippines

Re: Dacor HP seat problem

Just to close out this topic, a week ago, I got my package from the US and got a Dacor seat from Bryan. It freshened up quite nicely, and after installing it into my reg, I was able to get it back into the water:

It worked well enough (well, as good as can be expected I guess) that pretty soon, I didn't really notice the WOB when I was playing around with my camera. Thanks for the seat, Bryan!

Also in the mail: My VDH plate!

While I was already using a modified plate with a cutout to accommodate the reg, one major reason for me to shift to the VDH plate was that I could use 2 cam bands on it as opposed to just one on my previous plate (the arrangement of the slots precluded me from using 2 bands on my former plate)

Gotta love that plate!

It worked well enough (well, as good as can be expected I guess) that pretty soon, I didn't really notice the WOB when I was playing around with my camera. Thanks for the seat, Bryan!

Also in the mail: My VDH plate!

While I was already using a modified plate with a cutout to accommodate the reg, one major reason for me to shift to the VDH plate was that I could use 2 cam bands on it as opposed to just one on my previous plate (the arrangement of the slots precluded me from using 2 bands on my former plate)

Gotta love that plate!

_______________________________

Ed

Ed

Return to “General Discussions”

Who is online

Users browsing this forum: No registered users and 17 guests