- I bought this DAAM on Ebay (Below - "Before" pictures)... Looked pretty decent, Huh?

- Ugly nozzle... Followed by Ugly Insides.

- Now for the "Mystery"... Further disassembly revealed a nearly brand new high pressure seat and nearly new old stock (NOS) low pressure seat.

- I can't help wondering about this. Why would somebody stick new parts into this crummy mess? But then it kind of looks like a cleanup was attempted... And salt residue indicates it must have been tested in salt water.

- This next bit of evidence solves it, I think.

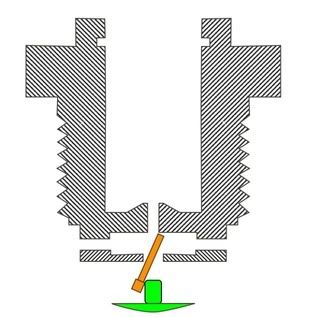

- The pin support was damaged and difficult to separate from the nozzle. The nozzle is damaged where the pin goes in. And the yoke screw is bent.

- I think the guy who rebuilt this last, got the pin in there cockeyed when he re-assembled. When he pressurized the regulator, it locked up and he couldn't get the pressure to release. You can press on the pin support thru the center of the adjusting screw to release pressure. But that wouldn't damage the pin support and nozzle opening. I think he stuck something thru the center of the adjusting screw and hammered on it. This damaged the pin support and the nozzle opening and I think is probably what bent the yoke screw... As the tank was resting against it when the hammer struck.

- What do YOU think?