At any rate, at the time, I made a makeshift diaphragm from my Mistral's old diaphragm, cleaned it up , and it worked well enough to take into the pool:

Bear in mind that at this point of the restoration, I was still using all the original parts (except for the diaphragms of course)

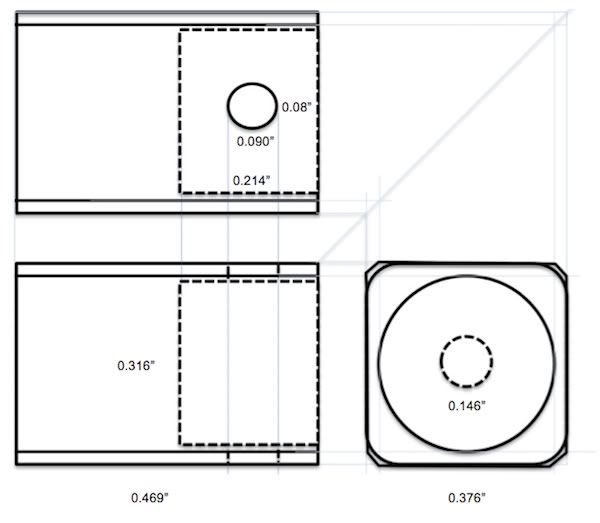

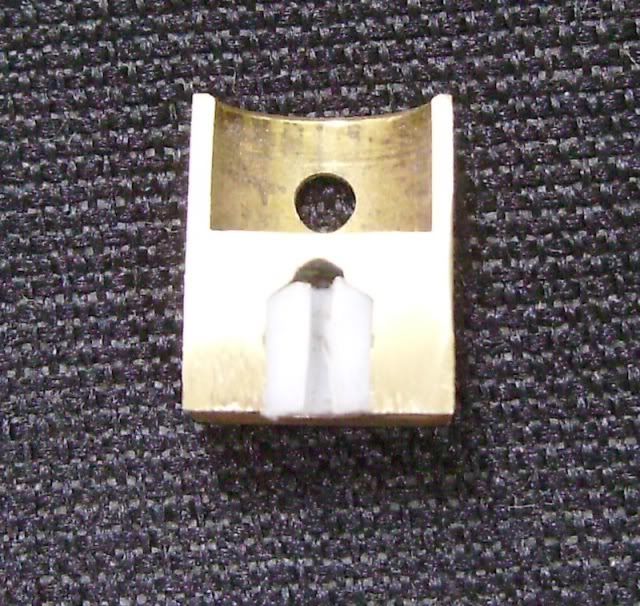

Fast-forward to this week: I was able to acquire some NOS diaphragms to bring my Dacor to a more original state:

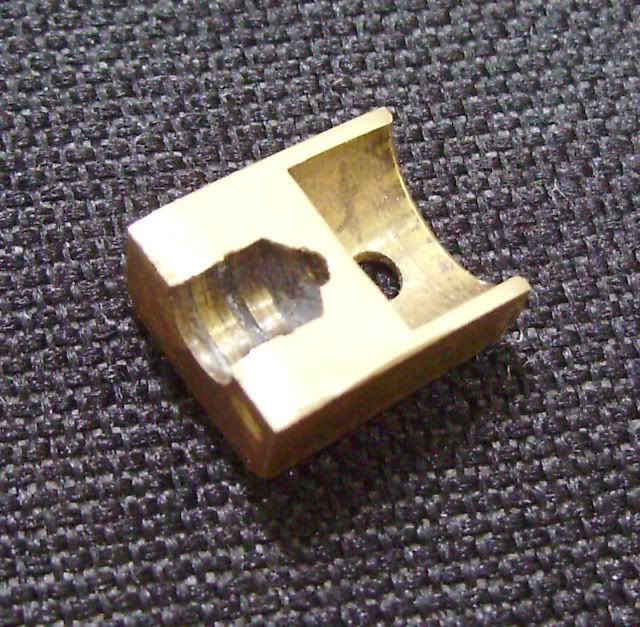

Slapped them on and tested them on the bench and they worked fine and actually breathed kinda nicely! Was quite excited to see how they'd perform in the pool, but when the time came, I slapped the reg on to a charged LP72, turned the valve on, and... Nothing! I looked through the exhaust holes in the can and saw that the diaphragm was fully depressed, but still no air. Disassembled the cans (tank valve off, but still under pressure because I was unable to turn the yoke screw) to check the levers, but they were in place, and even manually depressing them produced no air. Apparently it was a 1st stage problem. Got the cans off to expose the pin and tried depressing that as well. It sort of was able to "squish" in, but surprisingly still no depressurization. At this point, I got this feeling that having the pin all exposed like that under pressure and not behaving the way it was supposed to was a bad thing, so I pointed it away toward the pool. Right after doing that, I heard a loud pop and the push pin got shot out into the pool. There was also now this slight hiss as the remaining pressure escaped, but it was a few seconds more before pressure dropped low enough that I was able to unscrew the 1st stage from the tank.

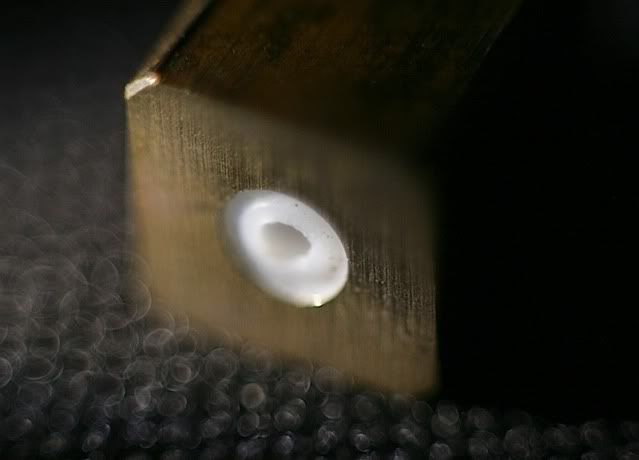

Post mortem revealed a HP seat that looked like this:

Now I don't have any other Dacor seats to compare it to, but I'm assuming that there's supposed to be a metal insert in the middle of the soft seat for the pin to actuate upon? I'm guessing that there was some delamination allowing air to creep along the sides, towards the middle, and out the middle. Does anyone have a photo of an old Dacor seat?