Page 1 of 3

DA Aqua-Master Mystery Mess

Posted: Tue Jan 03, 2012 11:59 pm

by SurfLung

- I bought this DAAM on Ebay (Below - "Before" pictures)... Looked pretty decent, Huh?

- Ugly nozzle... Followed by Ugly Insides.

- Now for the "Mystery"... Further disassembly revealed a nearly brand new high pressure seat and nearly new old stock (NOS) low pressure seat.

- I can't help wondering about this. Why would somebody stick new parts into this crummy mess? But then it kind of looks like a cleanup was attempted... And salt residue indicates it must have been tested in salt water.

- This next bit of evidence solves it, I think.

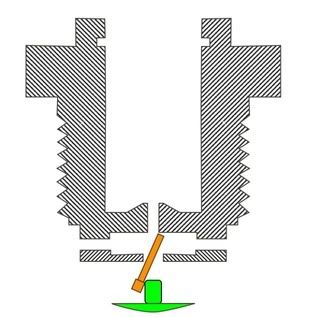

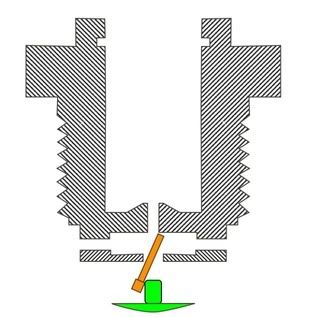

- The pin support was damaged and difficult to separate from the nozzle. The nozzle is damaged where the pin goes in. And the yoke screw is bent.

- I think the guy who rebuilt this last, got the pin in there cockeyed when he re-assembled. When he pressurized the regulator, it locked up and he couldn't get the pressure to release. You can press on the pin support thru the center of the adjusting screw to release pressure. But that wouldn't damage the pin support and nozzle opening. I think he stuck something thru the center of the adjusting screw and hammered on it. This damaged the pin support and the nozzle opening and I think is probably what bent the yoke screw... As the tank was resting against it when the hammer struck.

- What do YOU think?

Re: DA Aqua-Master Mystery Mess

Posted: Wed Jan 04, 2012 12:36 am

by Drado

You may be on to something there, Eben. Do you have the original pin? It would be the clincher connecting the damaged pin support and nozzle:

My guess is though, is that upon pressurization and subsequently getting stuck, the only thing he tried to force was the thumb screw to relieve the pressure, as opposed to hitting through the center of the adjustment screw (unless there are indications of damage on the spring pad).

I also think its a franken-reg. I don't see how the body ring and other internals could be that corroded, yet the inside of the cans still look relatively good.

Re: DA Aqua-Master Mystery Mess

Posted: Wed Jan 04, 2012 7:35 am

by phsdive

From the photo it looks like the inside parts were given to long in (or to strong) an acid bath and the plating was partly removed. I had one like that and had the parts replated and they came up OK. Make sure you post 'after' pic's of this one. Good luck.

Re: DA Aqua-Master Mystery Mess

Posted: Wed Jan 04, 2012 10:56 am

by SurfLung

- The original pin is actually in perfect shape. BUT, the original nozzle and pin support are not to be trusted... I'm replacing them.

- I assembled the high pressure seat, spring, etc into a really nice nozzle I had left over from my first Phoenix conversion (done by Bryan). With a new VDH sintered filter and clip ring. I also have a like new pin support left over from that same Phoenix.

- This replacement nozzle assembly looks like new. I tested it (just the nozzle) on a tank... Works perfectly... HP seat works fine. So the main damage has been repaired.

- Yes PHS I agree: I think the extensive copper color indicates a bad clean-up attempt with acid or vinegar/water solution left in too long. The ugly stuff is going to be electroless nickel plated... The bead blast will clean them up nice and a nickel coating will keep them from ever corroding again. I might do the cans, too.

- I'm taking this one in steps... I was pretty bummed at first when I saw all the crud and damage. But, getting the nozzle fixed up has me encouraged. The rest of it, though ugly, looks to be structurally sound. This "Franken-Reg" might go all the way to Phoenix but I'm going to get it working right as a DA first.

Re: DA Aqua-Master Mystery Mess

Posted: Sat Jan 21, 2012 6:09 pm

by SurfLung

Electroless Nickel Plating and Re-Build...

- I decided to go ahead with re-building this regulator. First order of business was clean up and plating of the parts that were so badly pitted. You can see that plating pits doesn't make them look much better... Kind of like lipstick on a pig!

But electroless nickel is a superb protection from further corrosion.

- The ugliest parts are still in excellent functional shape and they're out of sight... And with Electroless nickel hermetically sealing every pore, they'll probably never corrode again.

- I installed a new small diaphragm and a new silicone large diaphragm. The low and high pressure seats were already new (as noted in the original post). New body gasket and new nylon gaskets went in. Everything adjusted up just fine... IP pressure, lever tension, etc.

- I also installed a new duckbill eliminator, new black silicon hoses with streamlined wagon wheels and cup shaped valves. New curved mouthpiece. It is now a like-new (or better) DA Aqua-Master that just happens to have some ugly looking parts inside.

- I've dry tested it with high (3000 psi) as well as low pressure tanks and it breathes really nice. Oh and I refinished the cans with electroless nickel so they look pretty nice.

- I cleaned up and re-painted the original label with flat black. And even though the label was damaged by the previous owner, it doesn't look bad... I think this regulator now has some "Character"

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 10:55 am

by captain

What did the electroless nickle cost. I have been considering having it done to a DAAM.

I believe the original USD dull finish was electroless nickle not any type of chrome.

It has the advantage of getting into all the cracks and crevices that chrome can't.

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 12:50 pm

by scubasteve59

Captain,

Quick search brought up these guys:

http://www.caswellplating.com/kits/electroless.htm

I have not tried nor can vouch for them, but am interested in learning how to do this for my needs. I have a good shop setup for this sort of project.

Steve

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 1:21 pm

by 8dust

That looks pretty slick Steve.

Would be great to hear from someone out there who has tried one of these DIY kits...

I can think of several applications around the house here, right off the top of my head. I've always really like a nickel finish on things... chrome can look a little pimp-daddy at times, and that muted nickel seems kinda classy-er in certain applications. My nickel-plated Beretta w/ walnut grips would have to agree...

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 1:33 pm

by scubasteve59

10-4 Freddo...there is a guy on youtube that plated his Kimber frame with this kit and has a two year follow up video...still looks good. I might just have to get a kit and give it a try. I have a 380 nickel plated Bersa that is one of my fav's from asthetic's viewpoint.

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 3:12 pm

by Bryan

I tried this on some steel parts several years ago and I had ZERO success. It always came out looking like dull grey paint no matter how often I tried. Complete waste of money in my opinion.

http://www.caswellplating.com/kits/copychrome.htm

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 5:25 pm

by captain

There is a large electroless nickle plating company about 30 miles from me, just never got over there yet.

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 6:09 pm

by Drado

captain wrote:What did the electroless nickle cost. I have been considering having it done to a DAAM.

I believe the original USD dull finish was electroless nickle not any type of chrome.

It has the advantage of getting into all the cracks and crevices that chrome can't.

I bet Eben just dropped it off at work and got it done for free

Re: DA Aqua-Master Mystery Mess

Posted: Sun Jan 22, 2012 7:03 pm

by eskimo3883

Its a lot of extra work to take and upload photos. I really appreciate the effort put into showing the re-work process and the tricks learned.

I like the look of bare EN but Salt water is not a friendly place for bare electro-less nickel. I don't see this as the last time the bare EN plating will need attention. If there are a few more dollars in the budget I would go for dull chrome. At one point I also suspected early USD cans were just EN plated but based on my own XRF measurements I am 100% certain the dull chrome on early US divers is a chrome layer over EN plating.

I have held several of our DB's dull chrome cans in one hand and a "Grade A" original USD dull chrome can in the other and they are the same. Some how he even delivers the same original "grain" pattern. The real magic DB delivers is those pits would be filled with metal, polished, and plated over. The pits would be physically gone and electro-chemically stable. I have seen him do this with cracked cans that leaked air. He does the same quality job on internals, also does a beautiful job on shiny chrome and I know guys who pay more for their monthly cable than he charges for his plating.

Re: DA Aqua-Master Mystery Mess

Posted: Mon Jan 23, 2012 12:14 am

by captain

Re: DA Aqua-Master Mystery Mess

Posted: Mon Jan 23, 2012 3:25 am

by eskimo3883

The way I understand things the weakness of bare nickel is in its hardness not its corrosion resistance. The corrosion resistance of fresh EN is great. Its protection comes from the contiguous hermetic seal it forms. It can handle pretty corrosive environments in non-contact environments but it's so soft it would be expected to wear quite badly om external surfaces like a reg. Once the nickel layer wears you are back to patchy brass in sea water. The chrome is hard enough to prevent wear of the nickel and maintain the nickel's corrosion protection as a barrier film. At least on external surfaces the nickel would not be expected to last without chrome.