Do not dispair, all is not lost, in fact, this is really a good thing. A true vintage oval mask originated in the 1950s and 1960s. These masks have bands that had screws and nuts of some sort to hold the lens in the mask skirt. When I get a more recent mask with a band that has the slots and tab, I change it into a band with screw and nuts. Here is how I do it:

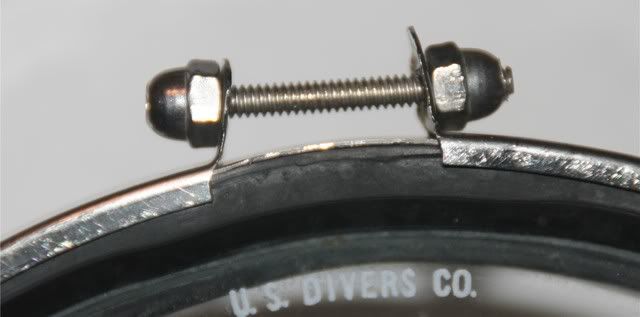

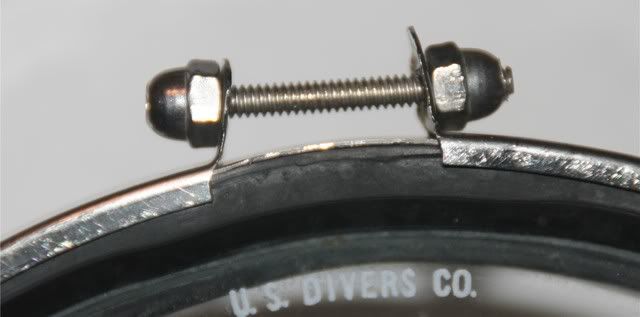

The verticle tab that the screw passes through is about 9/16" tall above the band. See first pic.

These taps hold the screw and nuts

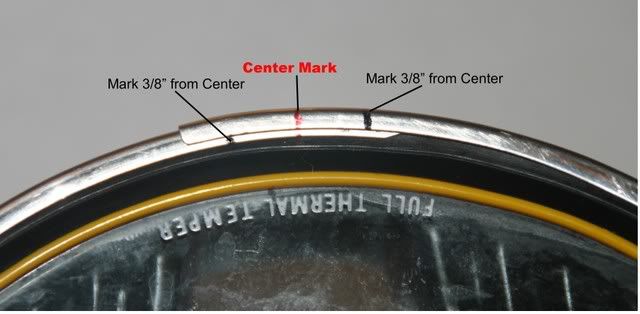

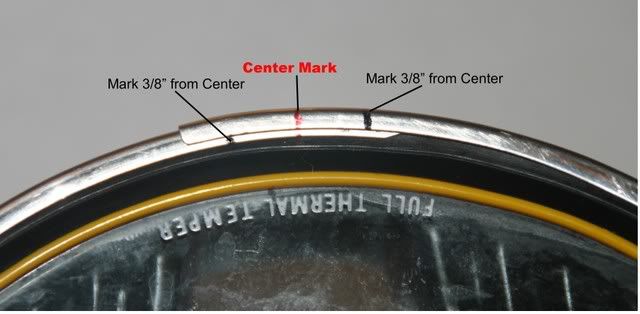

I place the band on my mask squeeze it as tightly as possible and make a mark on both ends to indicate the center of the band when in operation. From this mark, measure about 3/8" to the left.

Do the same on the other end of the band, except measure the 3/8" to the right of the center. You should still have the 9/16" left to make the tabs. I use a dremmel cut-off wheel, but if you are careful you could use tin snips or a hack saw to make a tab like this:

Once the two tabs are made, drill holes with a #28 bit.

Then bend the tabs verticle.

For the screw and nuts, I use a 1 1/2 inch #6X32 stainless bolt. The nuts are #6X32 stainless steel acorn or cap nuts. (Found at Home Depot).

You will have to drill through the nuts to allow the screw to go completely through them. I do this by first drilling with a #36 and then from the non-tapped end I use a #28; drilling only until I hit threads.

You will also need to put a small piece of stainless steel under the band, covering the area of the mask that the bands do not. For this I use a piece of stainless cut from a hose clamp.

The result is a more vintage looking mask and you have not lost the use of the band. PM if you need more info on this procedure.

Allan